Complete Ecommerce Supply Chain Guide [Updated 2023]

In this article you’re going to learn how to structure a modern ecommerce supply chain with a focus on the customer. We wrote it in digestible chunks making it easy to see how it all connects. Textbooks are for MBA courses and five-paragraph blog posts aren’t useful. This guide will thread the needle with comprehensive yet condensed insight you won’t want to miss.

In fact, many of these insights have helped us in the past. Shipium’s team consists of former Amazon and Zulily veterans. Many lessons learned there made their way to how we picture the modern ecommerce supply chain.

If you sell online and are looking to understand how to optimize your supply chain, this guide is for you.

What is the difference between ecommerce and brick-and-mortar supply chains?

Let's start with an obvious but important point: An ecommerce business is fundamentally different from brick-and-mortar (B&M), which means the supply chain that supports an ecommerce business is fundamentally different, too.

Some components of the supply chain are more important while others might not exist. For example, fulfillment centers (FC) are designed differently for ecommerce delivery, while distribution centers (DC) can be cut out entirely because there is no requirement to deliver goods to a storefront.

A few more key differences:

- On average the number of SKUs for ecommerce businesses is higher than B&M models, which means more variability with processes and packaging.

- Ecommerce inbound logistics focuses on optimizing allocation, whereas B&M inbound is about uniform distribution to DCs and optimizing delivery to stores (over/under stocking).

- Ecommerce inbound logistics can be directly associated with a customer order. For example, Amazon’s “More on the way” message means any purchases of the out-of-stock item will be immediately shipped to the customer when available.

- FC is focused on “single-piece flow” or streamlining picking to sorting to packaging an order.

- Returns are a different experience—go to the store versus print a label and ship back—making reverse logistics very different.

- Service Level Agreements (SLAs) matter more for ecommerce models, as the expectations are different for the movement of goods to consumers.

- Lastly, it’s easier to understand demand for a product that is out of stock due to the digital nature of ecommerce stores, as opposed to an empty shelf in a physical store. This has major impacts on demand forecasting, purchase orders, and allocation.

This guide starts from the orientation that you are first and foremost an ecommerce business.

Ecommerce supply chain strategy

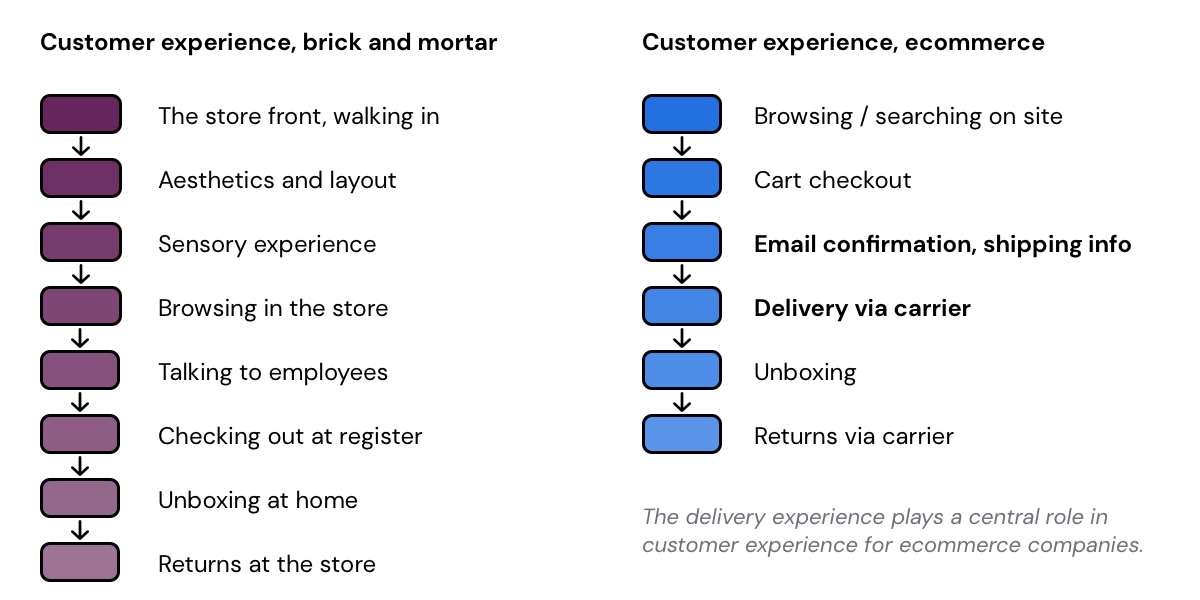

An ecommerce supply chain strategy is uniquely important. Unlike brick and mortar, the delivery of product is one of the few experiences customers have with your brand. In a physical world, experience is consolidated to store layouts and aesthetics, employees on the floor, touching the product in your hands, checkout lines, etc.

With ecommerce, customers primarily engage with your brand digitally via your site or apps, but secondarily with the delivery experience after purchase. As a result, availability, speed, and convenience all factor into brand experience. The supply chain now has an elevated role to customer loyalty and life-time-value.

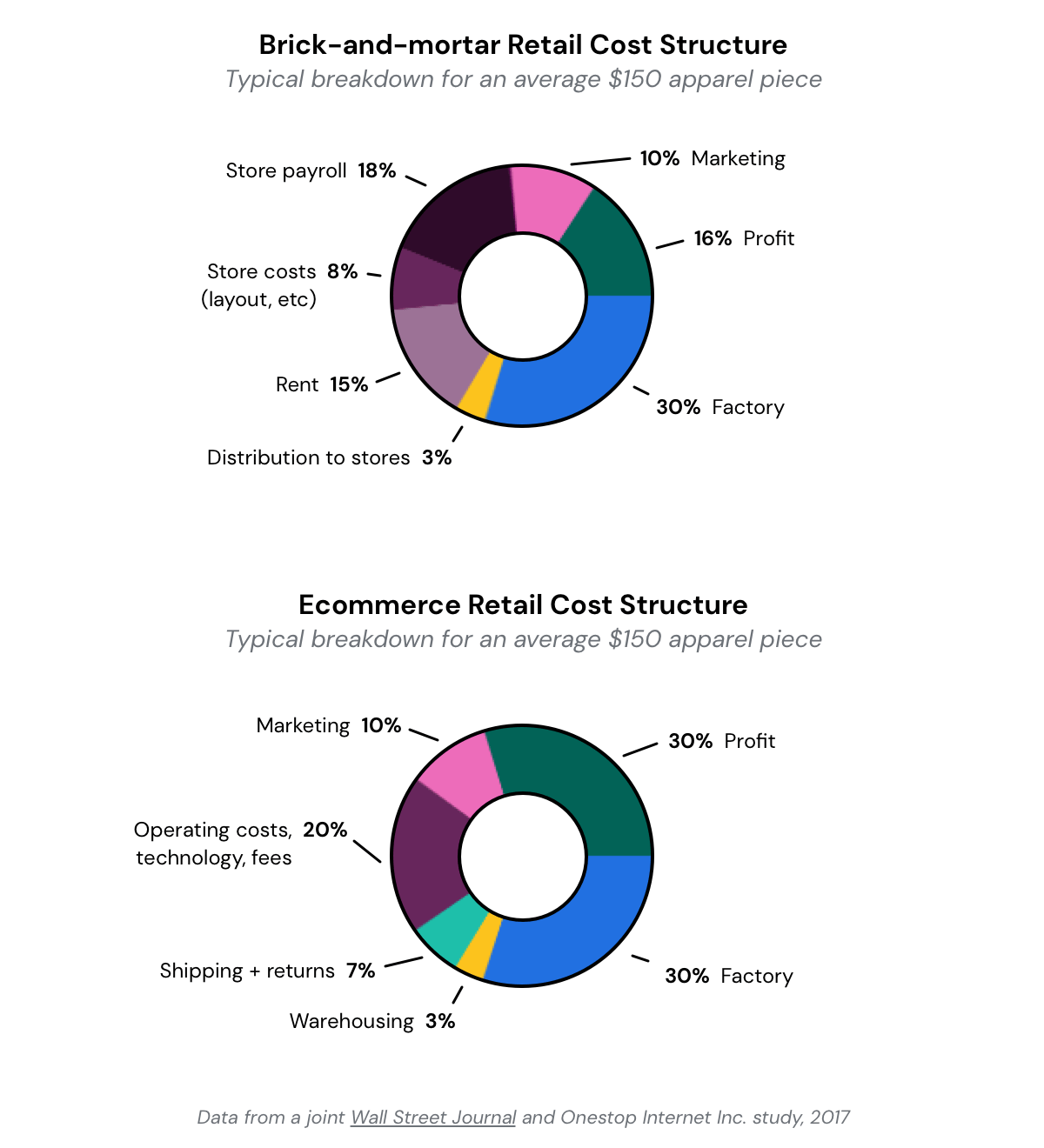

Your supply chain plays a strategic financial role, too. Ecommerce models will inherently require less capital expenditure in things like stores and employees, which means both capital and operational expenses within the supply chain become a larger share of total cost, like setting up a new FC (capital) or shipping cost per unit (operational).

With that in mind, reduction in costs has a much bigger impact on freeing up “found money” to reinvest into other parts of the business. This exact strategy is a major cause for winners and losers in the DTC space, in particular, and online retail more generally

It shows, then, that a modern supply chain with a focus on cost reduction will become a strategic differentiator for sales growth, which doesn’t really happen for brick-and-mortar models at scale.

Key metrics

Your business is shaped by what you measure, so it’s critical to get your supply chain analytics right. Smart ecommerce companies aggressively prioritize customer-centric metrics.

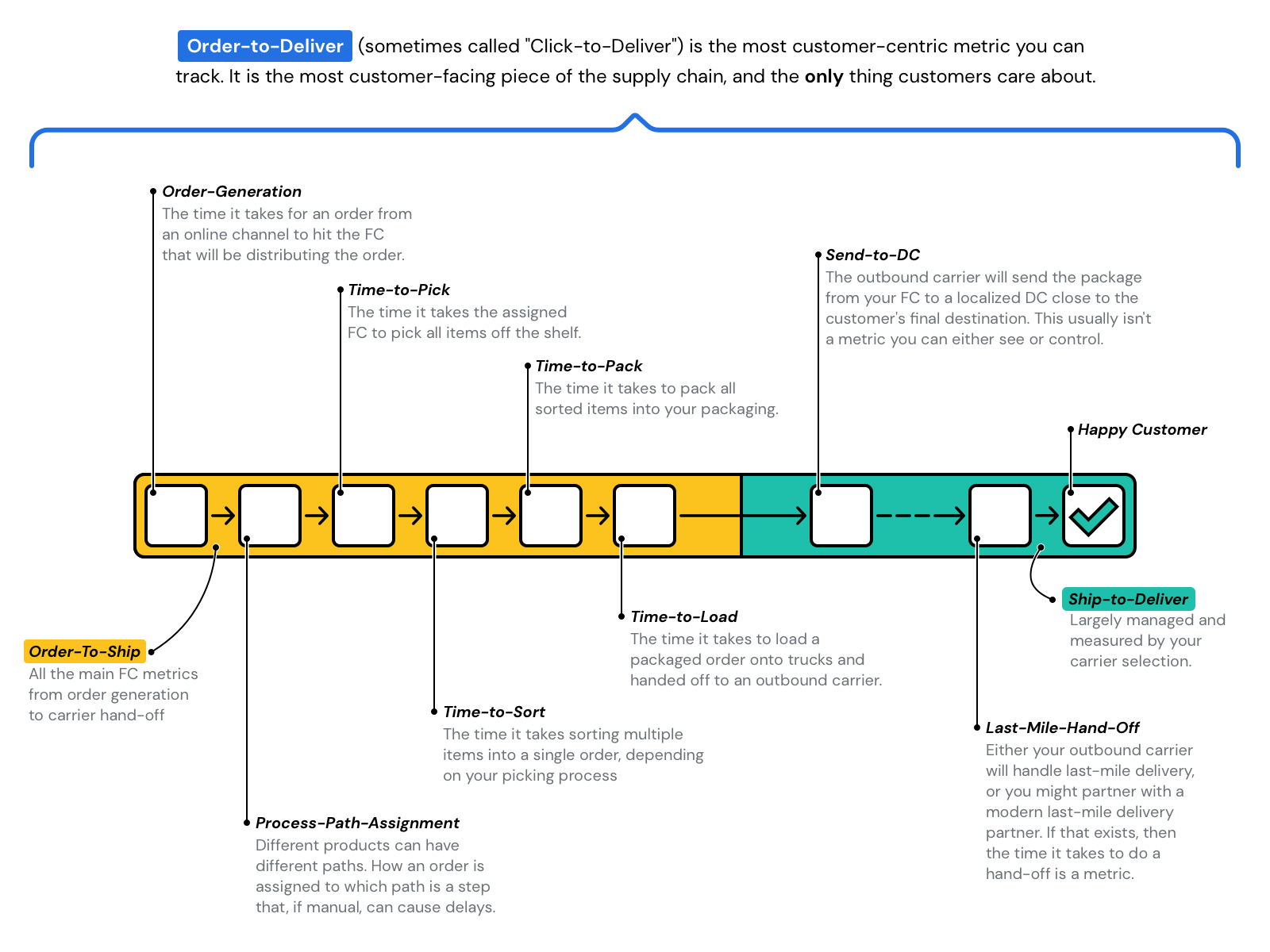

The most important metric: order-to-deliver, sometimes called click-to-deliver.

No metric better represents what matters to the customer than how soon they will get the product after they click purchase.

Traditional metrics like time-to-pack or click-to-ship are useful diagnostic tools, but should never be the priority measurement which shapes your operating cadence.

Order-to-deliver rolls up all kinds of metrics to give a single view into how well the supply chain is supporting the strategic initiatives of the business.

A few other customer-centric metrics to consider:

- Delivery promise accuracy — How often did we deliver when we said we would?

- Stock levels — The percentage of stock availability when a customer views a product page is directly related to brand perception and customer happiness.

- WISMO (Where is my stuff?) and WISMR (Where is my return?) are customer experience metrics that are intimately connected to reverse logistics performance.

- Recovery % — Returns are essentially a result of an exception farther upstream. By tracking the recovery percentage, you can gauge how successful your supply chain is performing.

Inventory placement and allocation

You can only ship stuff from where it's located.

With that in mind, the decisions around what inventory you place and where you place it makes a major difference to everything downstream.

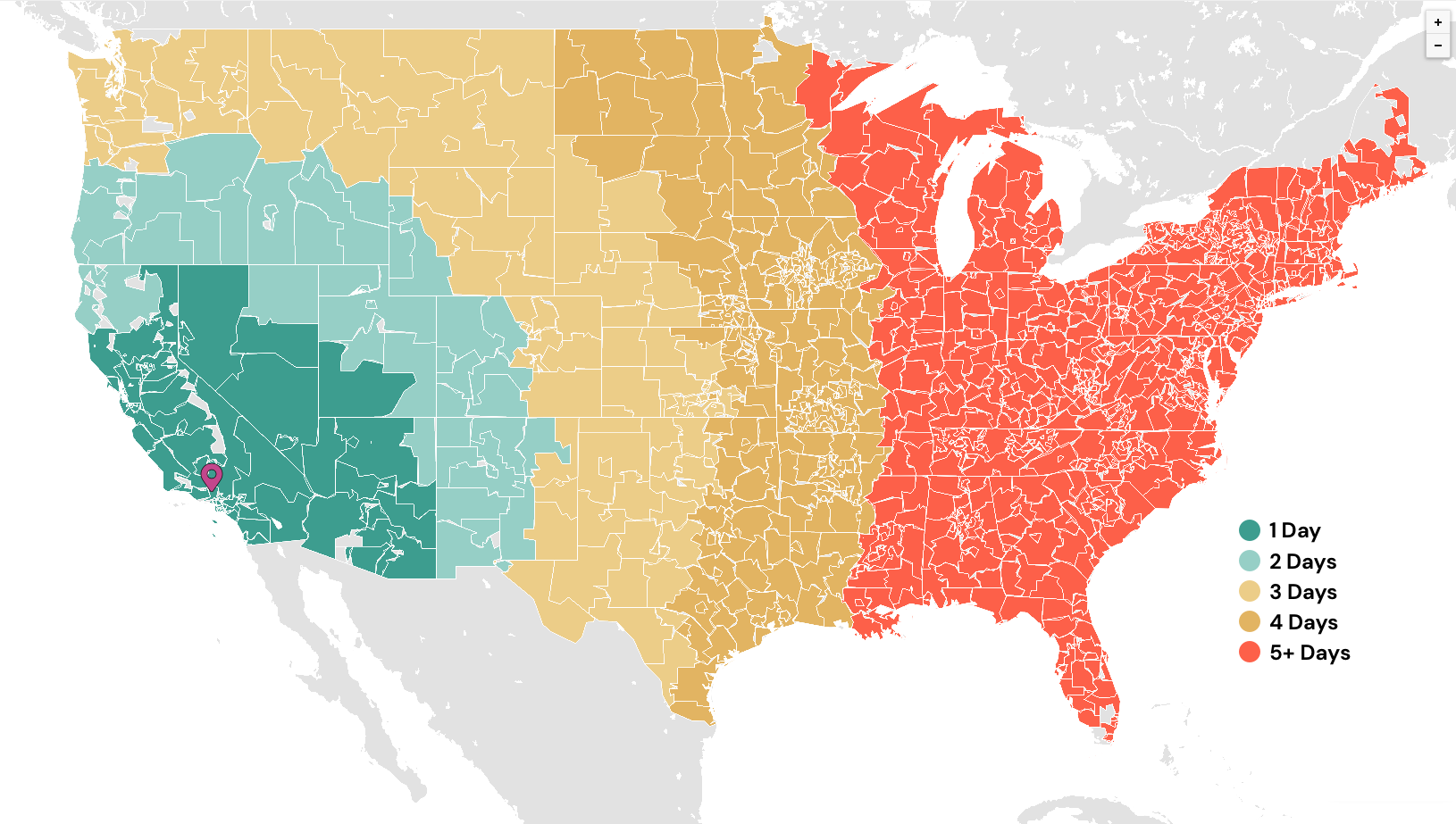

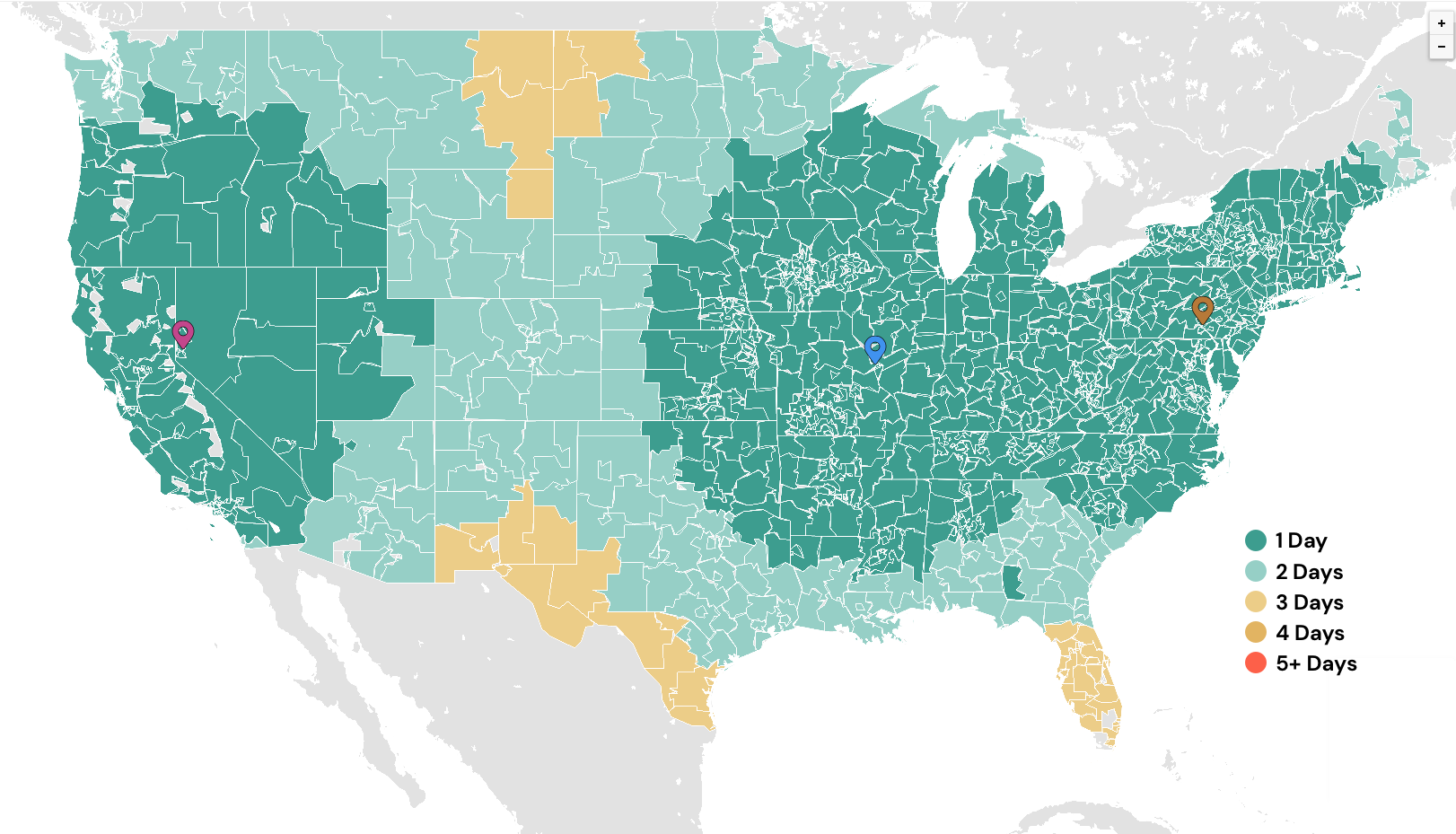

The big idea: The closer merchandise is to prospective buyers, the faster and cheaper delivery will be.

Intelligently allocating inventory across your network will open up the ability to offer fast or free shipping programs.

If you only have 1 fulfillment center in your network, then allocation is simple, but results will be poor. You'll cut off cheap and fast delivery to half your market.

Two FCs make a different, but now you need to decide how to allocate inventory. The following point is going to assume you have 2, 3, or more FCs in your network, even if using 3PLs.

Generally, putting all skews in all locations is a good first pass. If the physical attributes of your product are simple—small, light, consistently the same size—then it might make sense to always do it this way.

As companies grow and their SKUs differentiate, more complex strategies are needed.

Generally, most companies should plan allocation like this:

- Take the global forecast for a SKU.

- Analyze buying patterns for the SKU geographically.

- Attach cost structures to where that SKU is placed.

- Calculate the probable cost of storing and shipping that SKU to probable buyers per FC.

- Take those results and split up SKU allocation across FCs based on the outlay.

Inventory management (from a supply chain point of view)

What’s notable about inventory management within ecommerce business models is how much it’s brought into question old ideas. For example, ABC analysis was useful when data was harder to obtain, but with the computing advantage afforded by ecommerce systems, it may not be as useful compared to, say, probabilistic forecasting across all inventory decisions.

Decisions are a good way to think about inventory management. You will be making hundreds, if not millions, of decisions a day—Buy more of a certain SKU? In what size? Move that other SKU to a different FC? And so on.

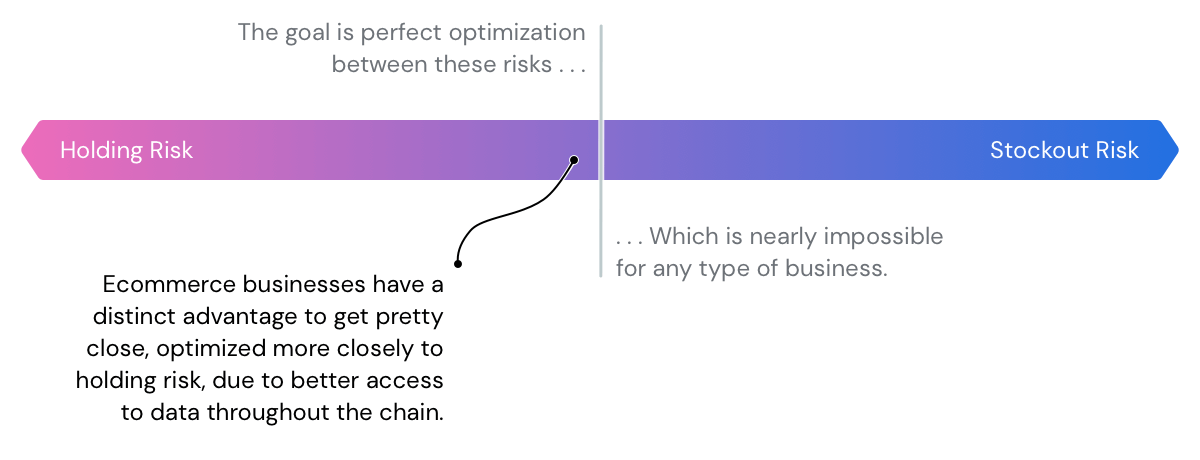

The accumulation of inventory decisions are meant to optimize your position along a spectrum of two risks:

- Holding Risk — The costs of maintaining inventory that isn’t selling.

- Stockout Risk — The lost revenue, or opportunity cost, of not having inventory available when people want to buy it, and that’s on top of additional hard costs like idle labor or under-utilized machinery.

The big idea for ecommerce companies: Perfect optimization in the middle is nearly impossible, but you can often get closer than brick-and-mortar models because of the ability for the entirety of the ecommerce supply chain to be interoperable. Buy an inventory management system that is modern enough to take advantage of the extra data available to you across modern partners, and the computational ability to push data-driven decision making.

A major factor to managing these risks, as well as reducing costs and improving customer experience metrics, is the location of FCs and inventory allocation to those FCs. We talk a little more about that below.

Delivery experience

The supply chain is directly responsible for customer delivery experience. Design, and subsequent improvements, can be charted along four categories.

- Speed: Customers want their products as fast as they can, within reason. Both industry data and our experiences show 2-3 days is preferable, and anything longer than 7 days is a deal breaker. Somewhere in 3-5 days is acceptable for certain goods, but you need to be transparent about the time.

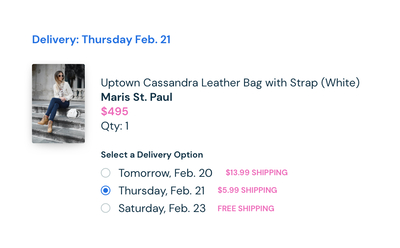

- Transparency: Which brings us to the second point. Customers want to know when they will get a purchased good even before they buy it. Transparency and accuracy up front are increasingly critical to cart conversion.

- Communication: Keeping customers updated during and after the purchase is becoming the main memorable interaction that determines repeat customers. When dates change and a customer doesn’t know, you can say goodbye to customer loyalty.

- Cost: Lastly, and possibly most importantly, customers hate to pay for shipping. You must make a choice on how to handle that preference, and the answer is up to your business. Recommendations: Bake it into the product price; slide some of the “found money” of cost savings elsewhere to subsidize cheap or free shipping; or eat it as a part of your margin and consider it an investment.

The culmination of all these points is what we call the Delivery Promise. Customers want a fast shipping option, that’s “free” or cheap, to see the delivery date up front, with good communication along the way.

We recommend an implementation of an Estimated Delivery Date to help increase cart conversion as high as 12%.

We recommend an implementation of an Estimated Delivery Date to help increase cart conversion as high as 12%.

All the links of an ecommerce supply chain

An ecommerce supply chain prioritizes some components more than others, and sometimes doesn’t even include legacy components. It’s helpful to first study as much as you can. Then the design is ultimately up to you, but here is the best basic design that any ecommerce business can use to plan their supply chain.

Demand forecasting and sourcing

Purchase orders, or procurement, can be managed differently for ecommerce businesses because it has the ability to be more intelligent than brick and mortar replenishment due to how ecommerce is inherently digital, with data more often centralized even when across multiple channels.

A few other things to think about:

- Because holding of merchandise is more centralized than across many stores, the standard benefit of volume breaks has an even more pronounced impact on profit. Consider investing in buying more inventory than you would initially expect.

- Lead time still matters but in a different way.

Placement

Initial placement, or “first allocation,” of orders can have one of the biggest impacts on unit costs. “You can only ship stuff from where it’s located” is a top principle at Shipium, which means deciding on where to locate merchandise has an enormous impact on costs. This insight also contributes to why most ecommerce companies are surprisingly too slow to expand to multiple FCs.

Rule of thumb: Place merchandise as close to the expected customer as possible to realize the maximum amount of savings possible.

More considerations:

- The sooner an allocation decision is made, the less cost allocation will be. This is why predictive analytics and demand forecasting are so intimately connected to first allocation decisions.

- Re-balancing is expensive, so getting first allocation right is so critical. Yet, re-balancing is a sunk cost that is still cheaper at scale than shipping goods from an FC far away from the customer.

FC/3PL management

Picking the right fulfillment partner matters. There are several strategies to consider:

- 3PLs who work only with ecommerce businesses will typically be a better choice because their design is best aligned with the needs of an ecommerce business.

- Your business is specific to you, which means it’s best to find a 3PL who specializes in your type of business. Some 3PLs specialize in large products like appliances; others specialize in products under 1 lb.; while others specialize in fashion and apparel whereas others electronics, and so on.

- The more automation, the better, although don’t over-prioritize or overpay for robotics or AI (yet).

- Interoperability of data matters.

- Returns is a critical piece to any ecommerce business model. Pick a 3PL partner who has a strong returns program, whether it be something custom you build, or tight integration with some of the modern returns solutions out there.

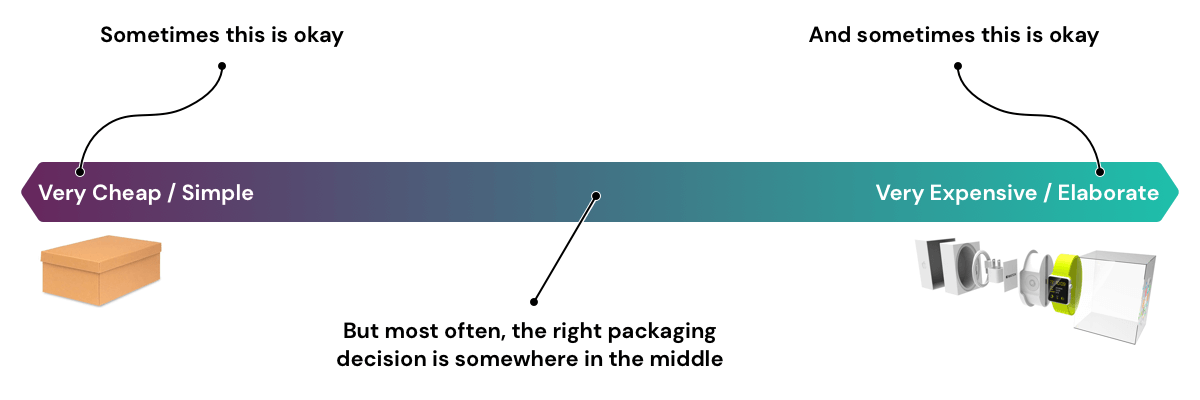

Packaging

Packaging is a critical part of the customer experience, but it’s also a major cost center, which means the variance of trade offs are pretty wide. It’s probably the part of the supply chain most contextual to your business’ needs. Some businesses should be totally optimized towards the cheapest packaging possible, while other businesses should have expensive yet experiential packaging. There is no right answer here other than whatever is best for your business, but generally, some trade off in the middle is best.

Because packaging is one of the key moments of physical engagement with customers, it also becomes a compelling area to invest in strategic differentiation. One of the hottest examples, among many, is sustainable packaging. While not only being good for the planet, sustainable packaging is growing in customer preference when making a purchase decision. But sustainable packaging is expensive and requires additional capital and process investments, which is actually a good thing for you. An old brick-and-mortar company may be too distracted to focus on improving its ecommerce packaging, which gives ecommerce companies an opening to create differentiation.

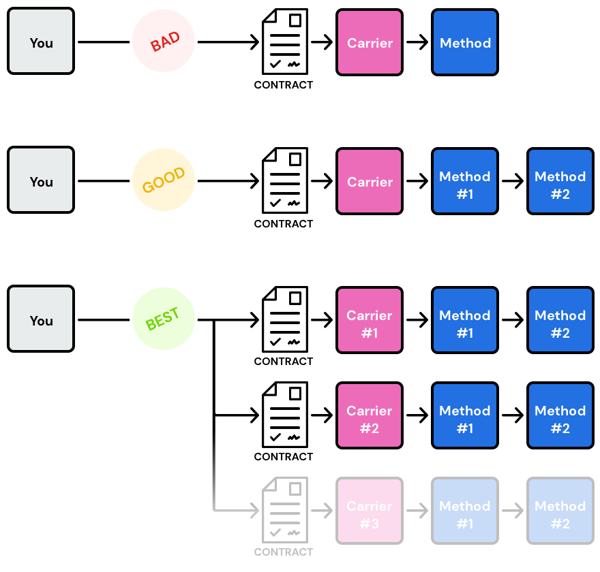

Carrier selection

It should be an easy decision to pick the fastest and cheapest outbound delivery option, right?

It turns out carrier selection is a puzzle most businesses struggle with. It becomes one of the key points of the chain where ecommerce models can squeeze out additional cost savings that can give the business an advantage at scale versus old brick-and-mortar competitors.

First, get the right contracts in place. Shop around by talking to the carriers directly (UPS, FedEx, USPS). But also talk with your 3PL partner or other possible partners who might have a contract that gives you even cheaper rates. In general, though, it’s best to not have multiple contracts via multiple parties going at once as it adds complexity to your system, while it is wise to consider multiple contracts with multiple carriers so you can scheme them off each other.

As much as $1/unit can be saved by intelligently picking between carrier options at the time of shipment generation. Much of those savings is tied to being close to the customer, which is yet another point to explain why ecommerce companies should invest in at least two FCs earlier than they typically do.

Post-order tracking

Shoppers expect transparency and communication, so the post-order experience is a key factor to determining repeat customers.

One key consideration is how post order tracking ties into your other systems. It’s not immune to interoperability needs. In fact, we are seeing many retailers look at “digital unboxing” as a key part of packaging (discussed earlier), yet much of the digital unboxing experience requires accurate post-order information via APIs.

Last-mile

Final mile delivery is expensive and difficult, which is why several companies have jumped into the space lately, from incumbents to startups.

Here’s the key point for ecommerce companies: Your specific business model will determine whether to work with incumbents like USPS or new startups. You might be just fine doing normal shipping with a regular carrier. But you might find major cost savings and a better customer experience with a specialty last-mile company like Roadie.

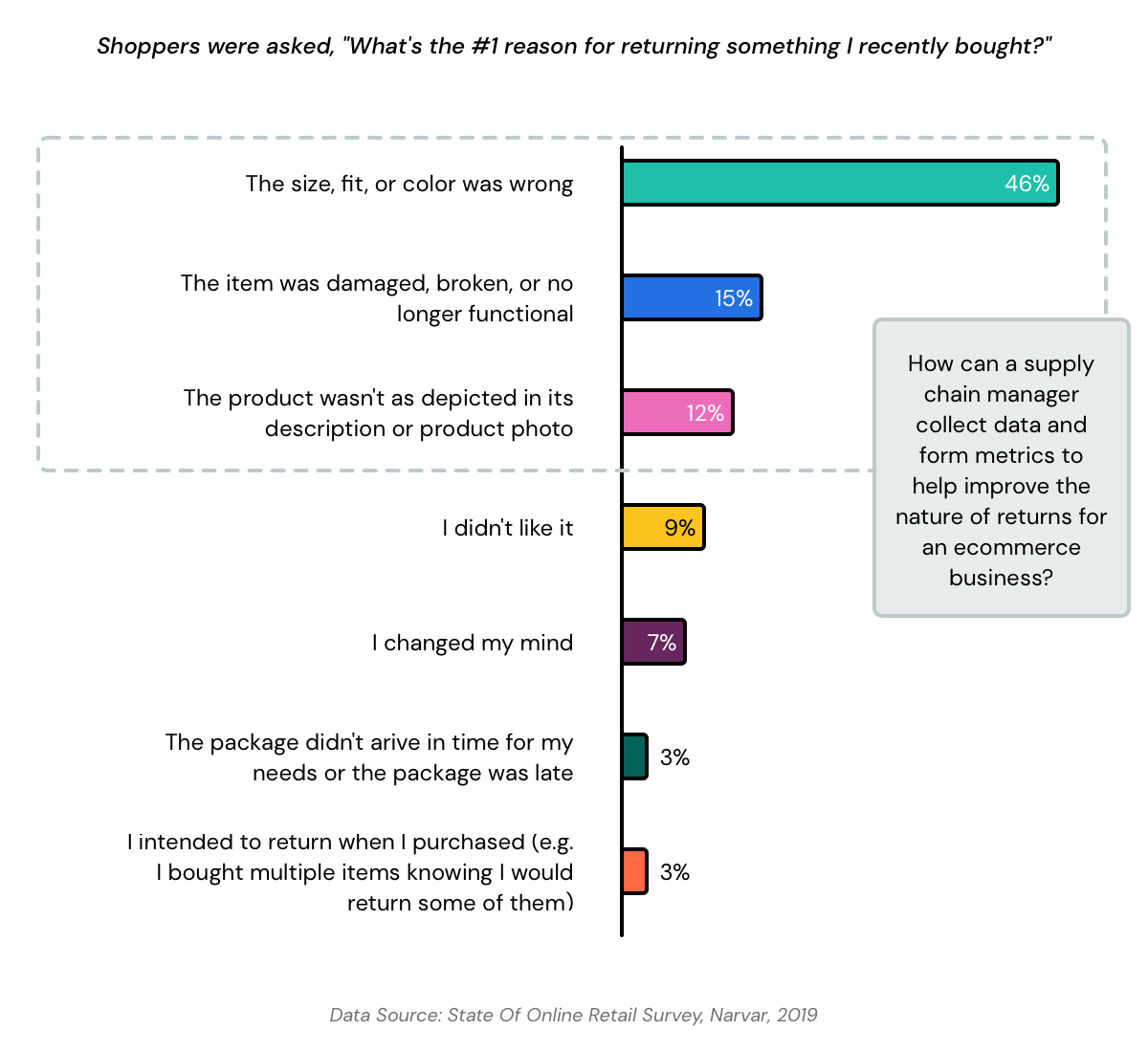

Returns

Returns are a big problem for ecommerce companies. They eat into margin. Consumer behavior has shifted over time, too, as the expectation that returns are free and easy is the norm. Industry data says that the majority of reasons for returns are retailer faults, but when digging into the numbers, it's more about consumer behavior evolving to expect they can return anything at any time for free, which means they buy a lot at once (usually to get free shipping) and then return what they don't want.

So the first thing to consider about returns is that the biggest positive impact is ensuring the process is inexpensive and doesn't cut into margin too much.

Beyond that, ecommerce businesses are especially sensitive to an ineffective returns process that negatively impacts customer experience. Not only are returns expensive, but a bad experience, such as asking customers to pay to ship a return, translates to as high as 81% of customers never returning for a repeat visit.

In short, a few guiding principles around returns has proven to be the best model for ecommerce businesses:

- Offer free return shipping.

- Do not charge a restocking fee.

- Make the return process hassle free, which could mean including a returns label immediately in the package, or, to save on costs, integrate across partners to make printing a label dead simple on your site.

- Present your returns policy clearly up front on the product detail page, since over 60% (same study) of shoppers check the return policy immediately before a decision to purchase.

Now, it’s your turn

One way to think about it is the classic 80/20 rule: 80% of ecommerce supply chains are consistent across companies so certain best practices can be applied, while 20% are different and specific to the needs of your business model. This guide is meant for the 80%.